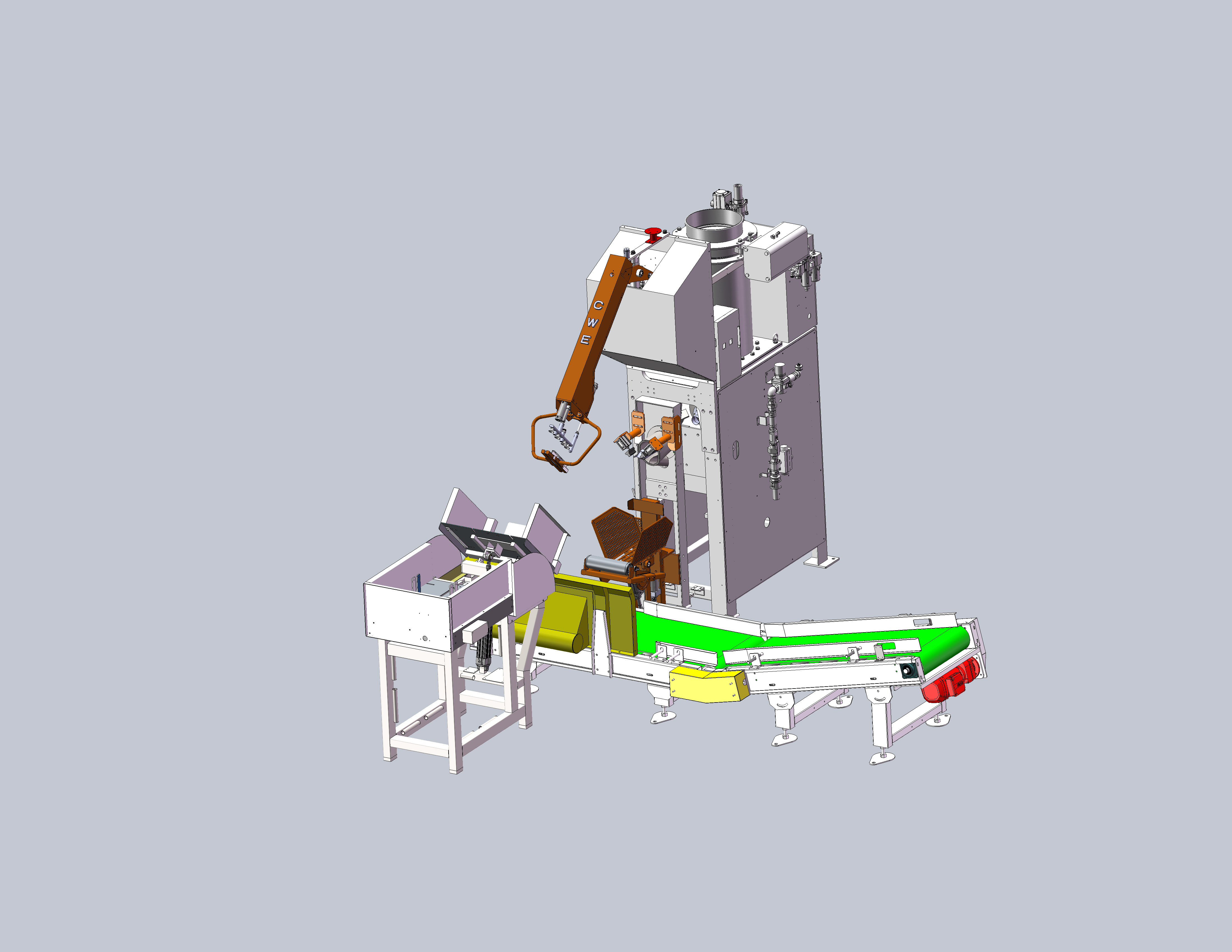

Model:Valve pocket packaging machine

P.V.P.E is the abbreviation of Pneumatic Valve Packaging Equipment. It is a pneumatic valve mouth packaging machine designed based on the principle of fluidized bed.

The main features include:

·Easy to clean and pollution-free when replacing new packaged products (through submarine type rear hatch)

·The air-blown feeding system, combined with patented weighing sensor technology, has high accuracy

·High capacity

·Simple operation

·Use world-famous industrial accessories and precision machining to achieve high-quality and durable equipment

·Manufactured according to procedures higher than Australian standards

·The pneumatic and electrical components are placed in the positive pressure electrical control cabinet to keep the sensing components away from dust

·Industrial high-strength wear-resistant butterfly valve, specially designed for high-friction products

PVPE (pneumatic valve pocket packaging equipment) is mainly used to weigh and fill powder, small particles or flaky materials into the valve pocket packaging equipment. This equipment is a gross weight weighing machine, and its specially designed fluidized bed system can give consideration to high efficiency and high precision when packaging. This series of equipment is equipped with the highest quality pneumatic and electrical components, ensuring its advantages of durability, simple maintenance and low use cost!

After 35 years of development, PVPE has been improving. It uses the latest automation components, from simple manual bagging to automatic bagging by robot. Various configurations can meet different packaging machine automation requirements. At the same time, other AWE products can be configured to realize the automatic production line from packaging to stacking.

Working principle:

When the P.V.P.E is working, the pressure in the storage bin of the packaging machine is different from that at the outlet (the position where the valve pocket is placed). The pressure difference makes the material flow into the valve pocket placed at the discharge port, and the speed can reach 4-8 bags per minute. The packaging speed is related to the specific gravity, fluidity, particle size, humidity, etc. of the material.

Typical materials suitable for PVPE include dry powder, mixed materials or granular materials with particle size less than 8mm.

If you have transformation or packaging requirements, please call our sales engineer for consultation at any time. This equipment can be customized according to your requirements and product characteristics.

Bag warehouse (empty bag placement machine):

A standard bag warehouse should have the following three characteristics: 50 empty bags can be placed in each position, usually three empty bag positions. After the empty bags in the current position are used up, the subsequent empty bags will be automatically sent to the suction bag position for packaging. The field operator can place a new stack of empty bags in the empty bag position, and there is no need to suspend production during this process, which ensures the continuity of the production of packaging bags.

Automatic bagging manipulator:

The inner valve bag is sucked up by the suction cup, opened, and then put on the discharge pipe by the mechanical claw. When the packaging machine detects that the packaging bag has been in place, the machine can start filling.