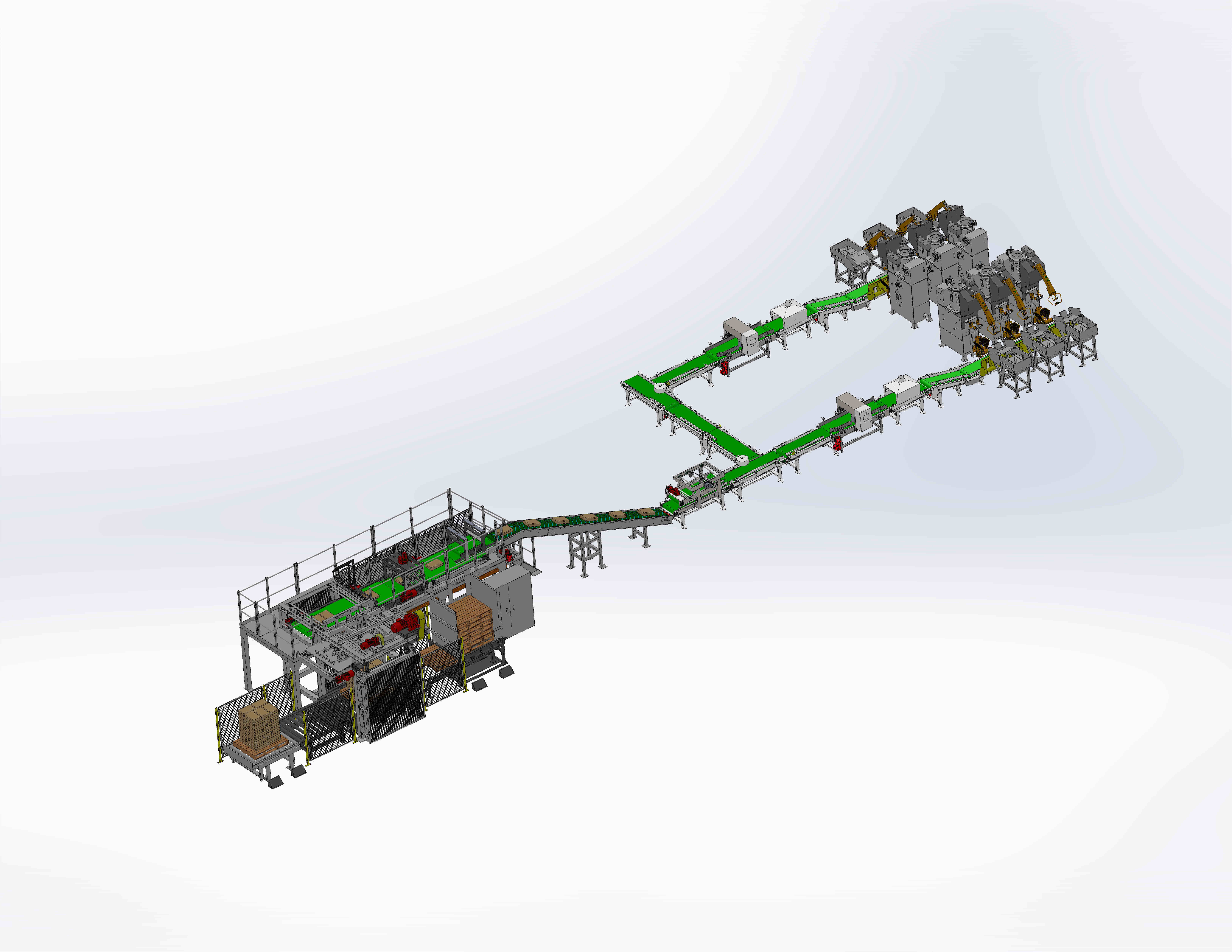

Model:Automatic stacking system

High-level stacker is a kind of stacking equipment, which has the characteristics of fast stacking speed, high stability and easy maintenance. It is mainly composed of climbing conveyor (or inclined c

Main components:

Climbing conveyor

After the materials are conveyed to the climbing conveyor by the crossover conveyor, the belt conveyor is conveyed to the indexing device of the stacker by the climbing conveyor to complete the waiting work of the indexing.

Indexing conveyor

When the packaging bag arrives at the transfer conveyor, the photoelectric switch will detect it. At this time, the two bag clamping plates on the transfer mechanism are controlled by the air cylinder, and the bag will be clamped after swinging 90 degrees; The main shaft of the indexing mechanism is directly driven by the servo motor reducer, which drives the bag clamping plate to rotate 90 degrees or 180 degrees, and then the bag clamping plate swings up and resets, so that the bag can be rotated at 90 degrees, 180 degrees and 270 degrees.

Marshalling machine

Belt conveyor is used for automatic grouping of bags (2+3 or 3+2).

Bag pusher

Push the grouped bags of the marshalling machine to the layering machine.

Layerer

The belt conveyor is driven by the motor and can be opened left and right, so that the grouped bags can be placed on the pallets.

The grouped bags are stacked on the pallets of the stack-tray conveyor through the layering machine.

Pallet bin

The main function of the pallet library is to automatically allocate empty pallets. The standard can store ten pallets. When a palletizing operation is completed, the current position of the fully loaded pallets will be replaced by the next empty pallet in the pallet library. All operations of transporting empty trays from the tray magazine to the appropriate position of the palletizer are automatically completed.

Pallet material: plastic or wood (specific material and size shall be provided by the demander)

Tray bin capacity: 10 empty trays

Tray conveyor

The chain conveyor, connected with the pallet storage bin, is responsible for automatically providing empty pallets to the stacker.

Stacking tray conveyor

That is, the heavy roller conveyor can transport and park two stacked pallets. The non-powered stacker block conveyor installed in the forklift area is equipped with a safety device to prevent the impact of the forklift.

Protective fence

Safety guardrails are provided to provide stable support and maintenance space for the stacker.

Control system

Siemens PLC (programmable controller), Schneider variable frequency speed controller and photoelectric position detection device are used to form the main body of the control system to realize the coordinated control of the whole stacker. The system has fault diagnosis and display functions, as well as perfect fault protection and interlock shutdown functions. The operation panel adopts Chinese and English identification panel. All button switches are French Schneider brand with reliable performance and long service life. The whole operating system is simple to use, complete in function and easy to repair and maintain!